Milcarb to Launch Remote Nitrogen & CO2 Beverage Gas Monitoring System

eXcelisys Builds Mobile IoT App that Delivers Tank Telemetry Directly to Android and iOS Devices

Gas (carbon dioxide and/or nitrogen) is a standard ingredient in beer. To achieve the ideal pour, pressurized gas is used to push the draught beer from the keg to the faucet. No gas = no beer. Milcarb’s N2UⓇ Nitrogen Generator provides on-demand nitrogen.

In most workplaces, it’s considered impolite to talk about passing gas. At Milcarb, that’s their job. For five decades, Milcarb has been a leader in the beverage gas industry. Milcarb’s gas-tastic innovations keep beer, craft cocktails, cold-brew coffee and soda flowing at restaurants and bars across the land. You can’t pour the perfect pint without a little nitrogen or CO2 to give it that bubbly mouthfeel. And who wants a flat, uncarbonated soda or seltzer? Yuck.

In most workplaces, it’s considered impolite to talk about passing gas. At Milcarb, that’s their job. For five decades, Milcarb has been a leader in the beverage gas industry. Milcarb’s gas-tastic innovations keep beer, craft cocktails, cold-brew coffee and soda flowing at restaurants and bars across the land. You can’t pour the perfect pint without a little nitrogen or CO2 to give it that bubbly mouthfeel. And who wants a flat, uncarbonated soda or seltzer? Yuck.

Based in Aurora, Illinois, Milcarb innovates, manufactures and distributes beverage gas systems, nitrogen generators and custom components that help beverage-serving businesses cut costs, reduce downtime and serve better drinks.

Milcarb’s ingenious product line includes the N2UⓇ Nitrogen Generator (makes unlimited on-demand nitrogen), the Carbo-Switch 5100™ (auto-switches CO2 tanks to eliminate disruptions) and the B2U Gas Blender (supplies the appropriate nitrogen/CO2 ratio to propel beer from the keg to the glass without disturbing the flavor characteristics).

A few months back, those crafty product designers at Milcarb brewed up another great idea – turning their dispensing switches into “smart” devices capable of taking measurements through sensors, then transmitting the data to gas distributors who may be located hundreds of miles from the tanks they maintain. “The Internet of Things (IoT) has become a rising trend in the past five years, even more so in the beverage industry as of late,” said Milcarb Product Engineer Taylor Turner. The new devices provide remote beverage gas telemetry monitoring.

A few months back, those crafty product designers at Milcarb brewed up another great idea – turning their dispensing switches into “smart” devices capable of taking measurements through sensors, then transmitting the data to gas distributors who may be located hundreds of miles from the tanks they maintain. “The Internet of Things (IoT) has become a rising trend in the past five years, even more so in the beverage industry as of late,” said Milcarb Product Engineer Taylor Turner. The new devices provide remote beverage gas telemetry monitoring.

Turner said the new Milcarb Switch-Series gas monitoring system (patent pending) is aimed at gas distributors and will offer them “more peace of mind” because they will know how smoothly their customers’ beverage systems are running at all times. Say you’re a gas distributor and you’re wondering if you need to drive over to the Old Town Beer Shack two towns over to deliver a new CO2 tank. Instead of trekking over to check the tank, you can check your Milcarb App. Or, say there’s some type of emergency. Open the Milcarb App and hit the “kill switch” feature to shut off the system without even setting foot on the premises. Great for emergencies or for customers running behind on their bills.

Bringing the Remote Beverage Gas Telemetry Monitoring System to Life

Milcarb has been manufacturing tank switches for years, but they had no IoT (Internet of Things) capabilities — until now. With the new system, Milcarb Monitors take measurements and collect data, then feed the data to the cloud through wi-fi or a cellular network. The Milcarb App — built by eXcelisys — accesses the data from the cloud (hosted by Amazon Web Services IoT) and delivers the data to users. The Milcarb Switch-Series monitors tank pressure, ambient temperature and battery power and can be retrofitted onto most systems.

The Milcarb Switch-Series is brand-new and currently undergoing a soft release to test the new remote beverage gas telemetry monitoring system.

Milcarb App Features (download free in the app store)

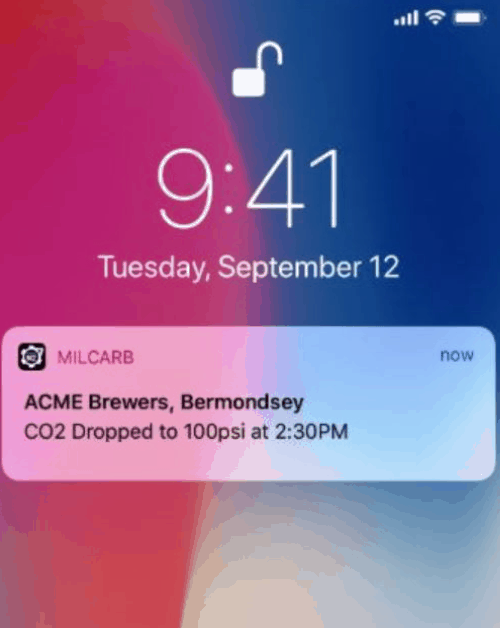

- Push notifications: pressure status alerts and notification when the system switches over to the emergency supply cylinder

- Intuitive user eXperience: uncluttered, easy-to-navigate screens

- Real-time monitoring: Nitro-Switch includes real-time temperature monitoring that can be accessed through app

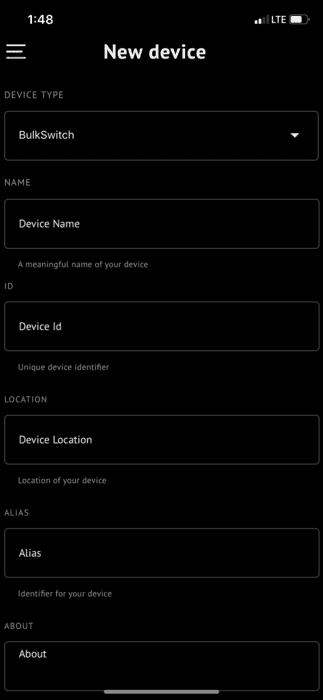

- Quick-start setup: Adding a new Milcarb Switch-Series device is quick & easy; app asks for device type, ID, location, etc., all on one screen

Milcarb Switch-Series – works in conjunction with the Milcarb App

- Carbo-Switch (patent pending): manifolds 2, 3, or 5 high-pressure gas cylinders; sends notifications via phone or email when main and/or emergency supply is depleting; monitors tank pressure; auto-switches from main gas supply to emergency reserves; distributes pressure readings daily at 9 a.m. and midnight — wi-fi and cellular capable

- Bulk-Switch (patent pending): Designed for bulk CO2 systems and featuring a remote kill switch accessible in the app; auto-switches to emergency backup and sends email notification at this time to request a delivery — wi-fi and cellular capable

- Nitro-Switch (patent pending): for blended gas systems; monitors main nitrogen supply generator pressure and emergency nitrogen supply pressure; “Run-Time Controller” will shut down nitrogen generator due to compressor overuse (such as system running constantly due to an issue with leaks, etc.); kill switch can be deployed through app; temperature sensor for real-time temperature monitoring — wi-fi and cellular capable

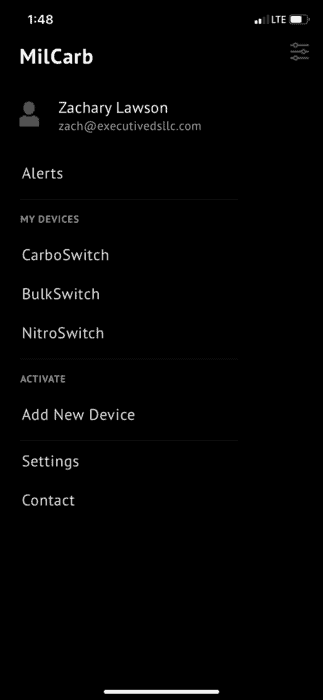

Milcarb App splash screen (above). Milcarb App home screen (below left). Selecting Activate > Add New Device on the home screen brings up the “new device” interface (below right), which walks users through the configuration process so they can add new devices and get the data flowing quickly.

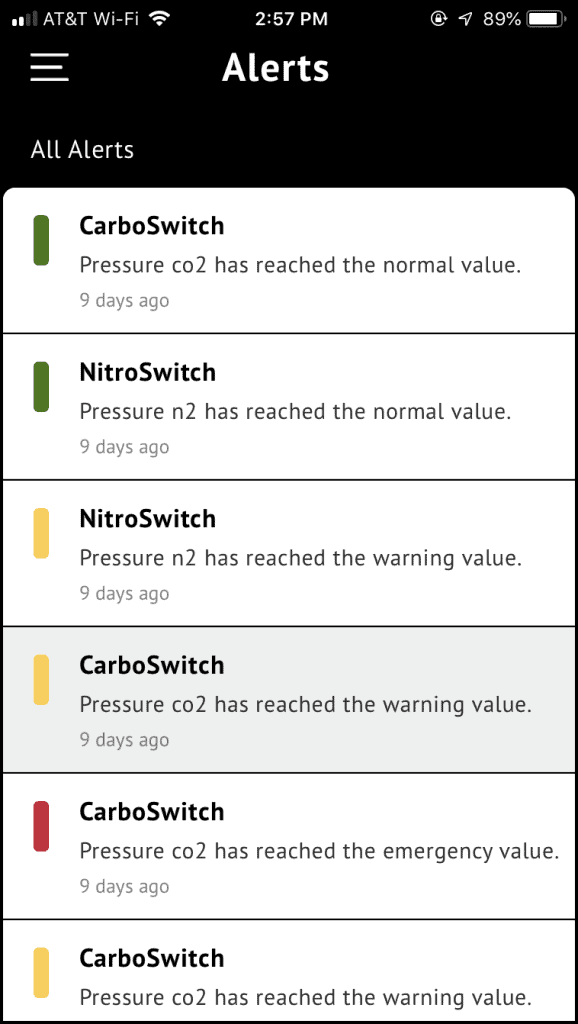

Above: Selecting Alerts on the home screen brings up this screen. Notice the alerts are “color coded” for status.

Milcarb App-building Process

The Milcarb beverage industry IoT mobile app was built by eXcelisys Web App Developer Zach Lawson working in conjunction with eXcelisys Project Manager Kurt Knippel. Initially, Milcarb envisioned a web app that would allow users to open a web browser and access the data — whether they were using an Android, iOS or Windows device. But web apps have some disadvantages: slower load times, data access problems (unavailable without an Internet/cellular connection) and a compromised user eXperience because the app cannot fully interface with each device’s built-in, native features.

Given the limitations, eXcelisys steered Milcarb away from a web app for a variety of reasons, including that a native app would allow for direct OS level push notifications (a must-have feature) without the need to integrate third-party services or requiring browser-specific workarounds. Native apps are installed directly on a device after downloading from an app store. This means they load faster. Native apps can be more eXpensive, though, because these smartphone applications have to be developed specifically for each mobile operating system — like Swift (iOS), Java (Android) and C++ (Windows Mobile).

To skirt the issue of having to develop separate native apps for each platform (iOS, Android, Windows), eXcelisys used React Native — a cross-platform app development framework that allows an app to run the same code on different operating systems. React Native allowed eXcelisys to develop the remote monitoring system for multiple operating systems using a single codebase (JavaScript), thus shortening the development cycle. In other words, React Native allowed eXcelisys to build three beverage industry IoT mobile apps in one. “I didn’t have to use separate coding languages for each one,” said Lawson. “This saved them time and money.”

Milcarb’s new Switch-Series brings a little IoT to the beverage industry, offering gas distributors remote beverage gas telemetry monitoring. After the device auto-switches a tank to the emergency back-up, it sends a notification to request a delivery.

In the end, Turner said that working with eXcelisys on the remote beverage gas telemetry monitoring system was an “overall positive eXperience,” although he thought that as design and spec changes were implemented, not everyone was on the same page with regards to communicating costs and vision. Initial discussions centered around a simple, web-based app but the switch to a native app raised the cost more than eXpected. “The product looks great, but we ended up paying more than we wanted.”

Costs for app development are always a tricky business, especially with custom development, said Knippel, the project manager. “We are building a custom solution the first time, every time.” As much as eXcelisys works to shorten and eXpedite the process, with custom development the entire cost is borne by the single client. In the case of the Milcarb app, said Knippel, the costs for Phase 1 of the development and the initial release came in within the estimated range as provided by eXcelisys at the beginning of the development process.

At a Glance: Milcarb

What: Designs and manufactures beverage gas systems and components to keep beer, craft cocktails, cold-brew coffee, tea and soda flowing at restaurants and bars. Founded in 1963.

Where: Based in Aurora, IL

Tagline: Good Under Pressure

Tech Specs: eXcelisys Milcarb “Alert” App

What: Milcarb App – download free in the app store; works in conjunction with the Milcarb Switch-Series (bringing a little IoT to the beverage industry)

How it works:

- CO2 and nitrogen tanks are outfitted with special Milcarb Switch-Series devices that have sensors to collect data on tank pressure, ambient temperature and battery power.

- The data is fed to the cloud through a wi-fi or cellular network.

- The Milcarb App accesses the data from the cloud (hosted by Amazon Web Services IoT) and delivers the data to a user’s Android, iOS or Windows device.

- The app sends push notifications (alerts) when the sensors detect an anomaly or when the system switches over to the emergency supply cylinder.

- In the event of a problem, the app allows users to send control commands remotely to the Switch-Series devices – i.e. there is a “kill switch” feature that can be eXecuted from the app.

- The app walks users through the configuration process to add new Switch-Series devices to get the data flowing.

Technologies: React Native, MongoDB, Node.js, AWS IoT

Challenge: When eXcelisys started the remote beverage gas telemetry monitoring system project, the Switch-Series devices did not eXist in the physical realm. They were an idea – a prototype under development by Milcarb.

Results: The Switch-Series and accompanying beverage industry IoT mobile app are currently enjoying a “soft-opening” release and will be available in 2020.

Ready to roll out the barrel on your own web app or native IoT mobile app? Check out our custom app development services.

Leave A Comment