Bio-storage Tracking System Complements Biopharma’s Breakthrough Therapies

Cancer Researchers Rely on Freezer Sample Management Software to Catalog & Track Lab Samples

As a biopharmaceutical company Tocagen has a clear, if not colossal, vision: “No One Should Die of Cancer.” Founded in 2007, Tocagen is best known for developing an eXperimental gene therapy treatment for a lethal brain cancer called high grade glioma. A glioma is a type of tumor that occurs in the brain and spinal cord. Clinical trials are ongoing. A few years back, Tocagen came to eXcelisys seeking a bio-storage tracking system to monitor cell samples at its facilities. eXcelisys developer Paul Spafford took on the role of “lab rat” and, along with eXcelisys Project Manager Kurt Knippel, devised a FileMaker Pro vial manager as innovative as Tocagen’s therapies.

To conduct its biomedical research and develop cancer therapies, Tocagen relies on cell line samples. These are stored in vials at Tocagen’s facilities. For eXample, Tocagen keeps U87 (Uppsala 87 malignant glioma) on hand, as well as CNS-1 (a rat glioma cell line). The list goes on and on.

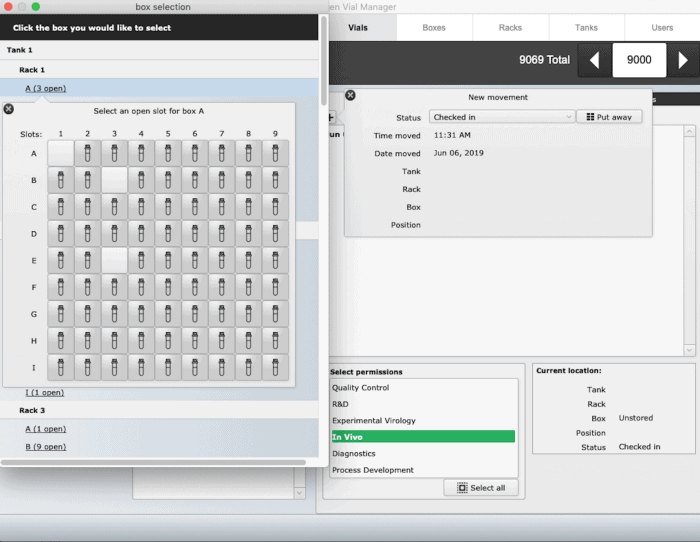

At any time, Tocagen might have thousands of these cell samples in storage. These samples must stay frozen. Picture industrial refrigeration units filled with thousands of cataloged tissue samples collected in vials. For storage, each vial goes in a box, and each box goes on a rack, and each rack is located in a nitrogen tank or cooler.

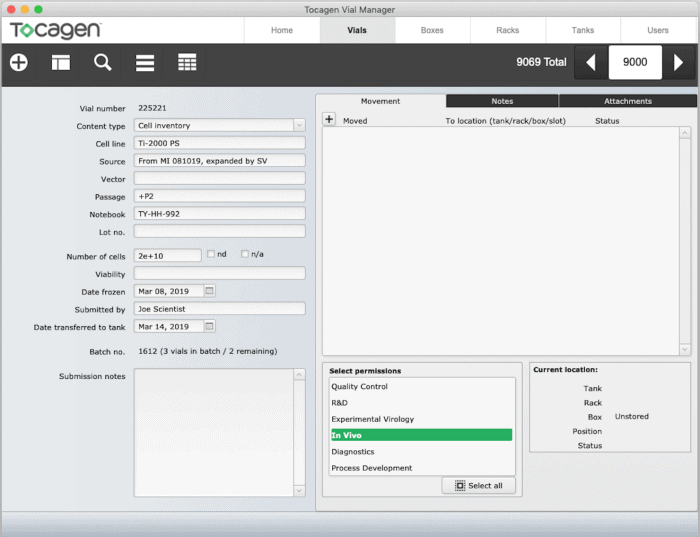

To aid research, Tocagen needed a bio-storage tracking system that could track the position (slot, box, rack and tank) of each sample in the lab so researchers would know what was available and where it was stored.

In addition, Tocagen needed an audit log to track the position of each sample as it moved about the lab. For purposes of sample integrity, Tocagen must track the contents of each vial, the cell line, the source, the lot number, the number of cells, the date frozen, the scientist who submitted the sample, the date it was transferred to a tank and every time and date it is moved and to what position it is moved to and by whom.

Since the new freezer sample management laboratory software went live in April of 2017, eXcelisys has built several more FileMaker database tracking systems for Tocagen labs, including ones that track reagents and specimens. All are riffs on the same idea, just tweaked for the needs of different facilities and groups within Tocagen.

The biosample vial storage tracking system also manages check-outs with a hierarchical control system that allows administrators to assign users to different groups and set which vials each group can access.

Bio-storage Tracking System: How it Works

FileMaker Database Bio-storage Solution Yields Positive Lab Results

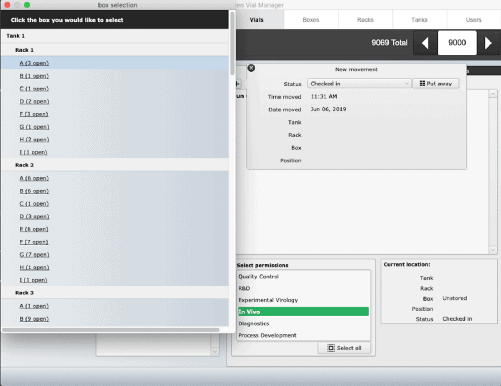

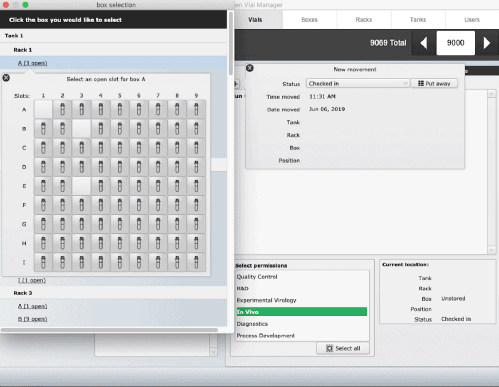

In addition to its storage-tracking capabilities, the bio-storage database also handles checkouts. Say a researcher by the name of Dr. Beaker needs a vial of CNS-1. Dr. Beaker puts in a request through the vial manager (via Filemaker Pro WebDirect) and the lab administrator receives a notification. The administrator can approve or deny the request. If the request is approved, Dr. Beaker will receive an email reply telling which specific vial of CNS-1 to access and where it can be found. By using WebDirect, Tocagen researchers can access the FileMaker app through any web browser on any device.

The freezer sample management software also aids with mass check-ins. Say Tocagen gets 150 vials of a cell line. The biosample vial storage tracking system will auto-assign slots based on availability. This saves a ton of time from the old system, which required researchers to physically look for open slots to store the vials in.

Tocagen Facility Lab Technician and Procurement Specialist Stacy Carlos served as Tocagen’s point person on the project. In discussing the process of working with Spafford and Knippel, Carlos had this to say:

“Both team members are thorough and detail-oriented. They communicate well and respond in a timely manner to ensure that our needs are met. They went up and beyond to assist us with improving another database that had been designed by another company. Needless to say, we made the right choice in switching over to eXcelisys.”

At a Glance: Tocagen (a global biotech company)

What: Known for developing a cancer-selective gene therapy, Toca 511 & Toca FC, for patients with brain and bladder cancer. Clinical trials and analysis are ongoing.

Where: Based in San Diego

How it Works: Tocagen’s products are designed to activate a patient’s immune system against their own cancer.

Tech Specs: the eXcelisys Workplace Innovation Solution

What: Bio-storage tracking system that tracks lab samples stored in freezers and used for cancer research

Technologies: FileMaker, FileMaker WebDirect, FileMaker Server

Solution: Using the FileMaker Platform, eXcelisys built a bio-storage tracking system (for specimens, cell lines & reagents) that provides a “digital window” into the storage freezers, allowing researchers to see where each sample is stored. The lab tracker streamlines the vial check-in process by showing which tanks have open slots available for storage. The system also tracks the precise location of each sample (tank, rack, box and slot) during its duration on the premises and tracks the contents of each vial, the source, the lot number, the date frozen and its location in the lab every time it is transferred to a new location, along with who moved the sample and when. The lab tracker also handles checkouts, allowing researchers to make a request for a cell line sample directly though the FileMaker app, which can be accessed through any web browser on any device.

Results:

– Sample check-in times reduced: Researchers no longer have to physically look for open freezer slots when new samples arrive because the laboratory software shows availability, allowing storage placement to be selected within the lab tracker.

– Sample check-out requests approved quicker: Researchers can request samples directly through the lab tracker and the lab administrator receives an email notification, allowing for immediate approval of specific samples.

– Specimen Integrity: Researchers can track the lifespan of a sample as it moves through the lab.

Leave A Comment