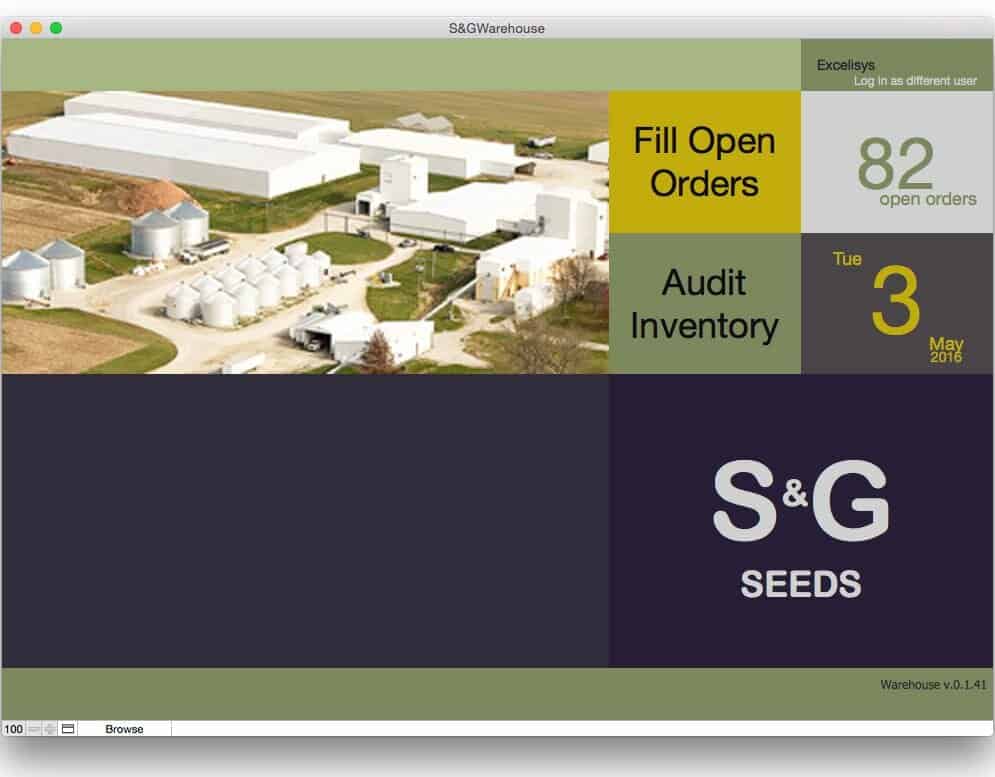

S&G Seeds – Warehouse-Inventory Logistics App

CLIENT S&G Seeds

DATE 2015

TAGS Agriculture, Consulting, Database, Design-Development, Desktop Solutions, FileMaker Go, FileMaker Pro, Mobile Applications, Professional-Services, Upgrades-Enhancements

About S&G Seeds:

In 1918, S&G Seeds put its mark on the world of agriculture by selling open pollinated seed corn to local farmers. As the years went on, the company expanded its territory and diversified from seed production to seed conditioning, warehousing, and delivery. Today S&G manages the intake of seeds from contract growers and the outflow of inventory to customers to and from their warehouses, along with a fleet of delivery trucks and drivers. Paper based processes became overwhelming, inaccurate, and completely inefficient.

Challenge:

S&G came to our crew at eXcelisys to give us a rundown of their issues. The picture painted was something like this (and please bear with me): corn, soybean, and wheat seeds of all different sizes come in from growers; they are cleaned, sorted, bundled, and manually labeled with contents and weight. The bundles, which can weigh anywhere from 300 to 1,000 pounds or more, are then taken to one of the five 100,000 square foot warehouses – depending on which one has enough room at the time – and stored on their enormous floor-to-ceiling shelves. (Pretty straightforward.)

Then as orders come in, someone walks from the office to a warehouse. With form in hand, which by the way was manually completed over a phone call, they come in, pass it on to one of the workers to pull the correct amount of bundles of the right seed and load them on one of the delivery trucks. If there aren’t enough bundles of a particular seed in that warehouse, they go to another to hopefully find the right amount to complete the order. (Still with me?)

Then before sending the driver to the address written on the order form, the number of bags loaded is checked off, the driver takes one copy (and depending on the author’s penmanship, is able to decipher where he needs to go), and another copy is walked back to the office.

During this entire process, papers get smudged, covered in dirt, mistakenly marked up with ink, misplaced, or lost and possibly inaccurately duplicated; and now that some bags are out of the warehouse(s), workers are left with an estimation of how many bundles remain.

Phew…that was an ear-, or in this case an eye-full, but hopefully I haven’t lost you, and can now tell you how we helped S&G clean that process up a bit.

Solution:

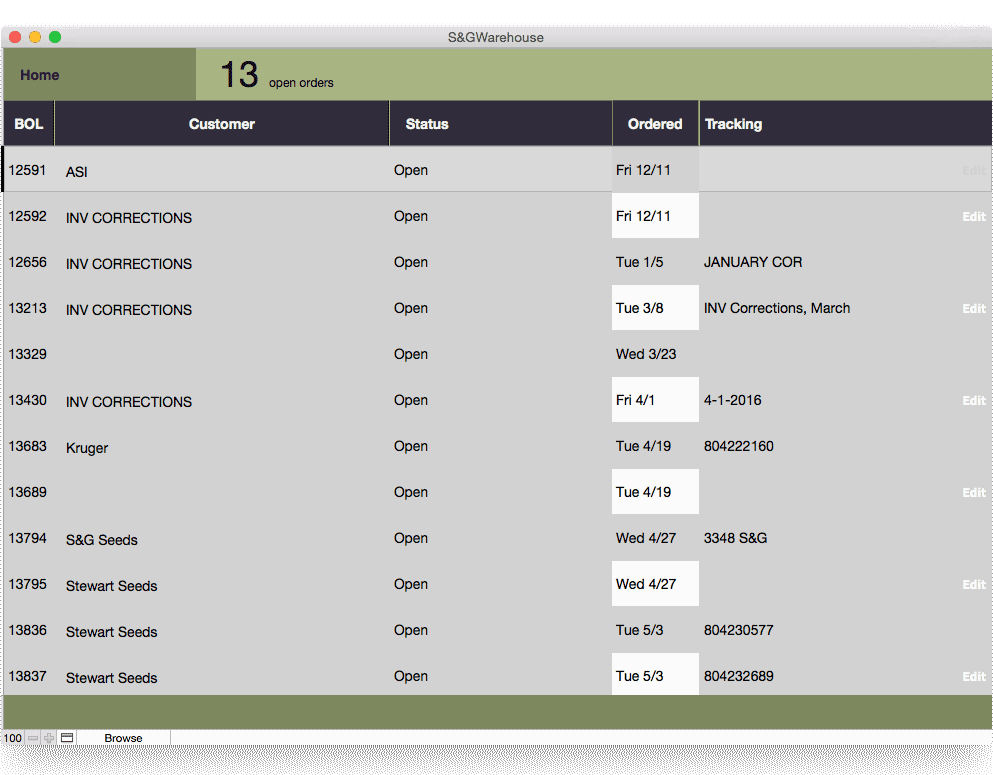

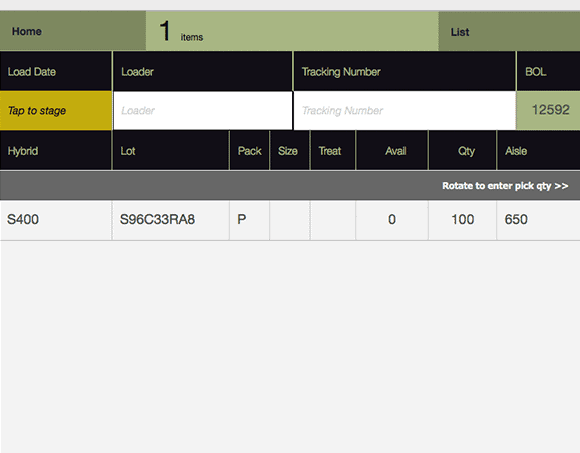

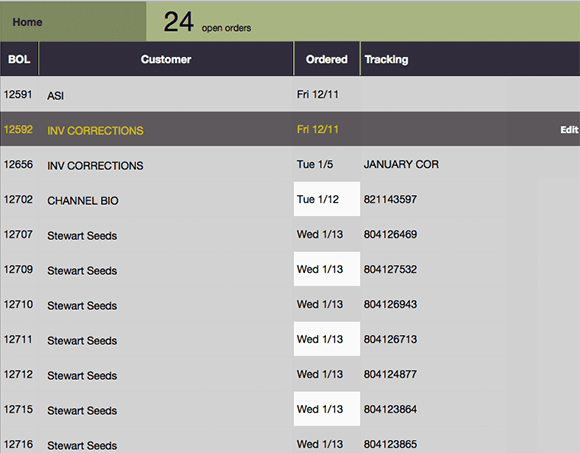

With the implementation of FileMaker Pro, we created a system for S&G that automated communication among the warehouses and back to the office. As deliveries arrive, a quick look at the screen tells everyone which warehouse has room for more storage; the new quantities and their location are added in the system, and all workers have a universal view of the now accurate inventory.

A similar process happens on the outgoing side when the office receives an order. Administrators immediately know if they will be able to fulfill it, and from which warehouse the bags should be pulled. No one is left guessing or deciphering handwriting, and credibility in the eyes of the customer is kept intact.

The great thing about FileMaker Pro is that there are always more options, which is exactly what S&G was later looking for. At their request, we mobilized their solution with FileMaker Go. In addition to fully automating their business and inventory processes, we set their personnel up with the ability to enter, update, and refer to information on the go through the use of iPads.

Results:

With FileMaker Pro and FileMaker Go, and of course help from the creative and dedicated team here at eXcelisys, S&G Seeds now runs its business processes efficiently. Entries are streamlined and legible, information sharing is easy and accurate, and the company is able to maintain its long established credibility. Workers can check inventory or the status of an order from anywhere on the property. And thanks to our warehouse inventory software, should they get a dirt splatter on the screen, or otherwise damage their iPad, the information remains intact!